Topic: History, Practice and Recent Development of Fatigue Research

Speaker: Xijia Wu (吴犀甲)

Structures and Materials Performance Laboratory,

Aerospace Research Centre, National Research Council Canada, Ottawa, ON, Canada

Time: 10:15-12:00, (Monday) May 7rd, 2018

Venue: Room 468, Lee Hsun Building, IMR CAS

Abstract

About one hundred seventy five years ago, a German scientist August Wöhler found fatigue cracks on the surface of an axle of locomotive when he investigated the train crash incident in Versailles, France, 1842. Ever since, characterization of materials’ fatigue properties has been a major task in structural and component design, mostly through experimental work. Fatigue design curves are mostly expressed in terms of traditional engineering design parameters such as stress and/or strain amplitudes, e.g., S-N curve or e-N curve. On the other hand, fatigue crack growth behavior is characterized with the linear elastic fracture mechanics quantity, i.e., the cyclic stress intensity factor, DK. But, ASTM standard load-shedding fatigue crack growth rate testing introduced crack closure and “fatigue threshold” phenomena. The question remains whether fatigue threshold exists under service loading conditions (rather than load-shedding conditions), which has important implications for holistic structural integrity analysis.

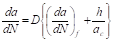

Recently, the author has revisited the Tanaka-Mura model and corrected the dimensional error in the plastic strain of the dislocation pile-up, which resulted in a new theoretical formula calculating fatigue crack nucleation life based on material’s Burgers vector, elastic modulus and surface energy. A transgranular fatigue crack growth rate model has also been developed based on the restricted slip reversal (RSR) process. An integrated creep-fatigue theory (ICFT) is further developed to describe the constitutive behaviors of materials subjected to general thermo mechanical loading and damage accumulation consisting of surface/subsurface crack nucleation and propagation in coalescence with internally distributed damage as promoted by creep:

(1)

(1)

Where (da/dN)f represents fatigue damage leading to either crack nucleation by dislocation dipole pile-up or crack growth by RSR due to mechanical fatigue,  is the internal damage factor, li and λi represent the size and spacing of internally-distributed damage, h is the incremental thickness of the oxide layer, and a¬c is the critical crack length.

is the internal damage factor, li and λi represent the size and spacing of internally-distributed damage, h is the incremental thickness of the oxide layer, and a¬c is the critical crack length.

In the above formulation, each type of damage is related to the mechanism strain derived from the constitutive equation for the responsible physical mechanism. The ICFT has been implemented in the finite element model (FEM) for component analyses subjected to prescribed boundary conditions and loading profiles. Examples are given to illustrate this physics-based holistic life prediction approach.

简历

姓名:吴犀甲

工作单位:Structures and Materials Performance Laboratory, Aerospace Research Centre, National Research Council Canada, 1200 Montreal Road, M-13, Ottawa, ON K1A 0R6, Canada

电子邮件:Xijia.wu@nrc-cnrc.gc.ca

学习经历:

1992.11 加拿大渥太华大学工程力学系博士(导师:阿列克塞.克劳兹, A.S. Krausz)

1985.05 中国科学院力学所硕士(导师:柳春图)

1982.07 中国科技大学近代力学系学士

工作经历:

1999- 加拿大国家研究院高级研究员

2013/8- 加拿大渥太华卡尔顿大学力学及航空系客座教授

1997-1998 波音应力分析工程师

1995-1997 加拿大国家研究院助理研究员

1992-1994 加拿大国家研究院博士后

1985-1988 中国科学院力学所助理研究员

科研方向及成果:

主要从事高温材料在疲劳和蠕变交互作用下的非线性变形机理本构关系及寿命预测研究,在Scripta Mater.、Mater. Sci. Eng. A、Int. J.Fatigue 和Int. J.Frature国际知名杂志及会议文集中发表论文百余篇,引用1191次。曾获加拿大科学院奖,加拿大航空航天最佳论文奖,五国技术合作奖等奖项。并任国际燃机学会3M 委员会成员,加拿大国家科学技术基金评审,学术刊物评审。主要研究成果如下:

1) 提出疲劳裂纹扩展的受限滑移循返(restricted slip reversal)模型,从而得到疲劳裂纹扩展速率指数的理论值,并推导论证了应力强度因子门槛值在真空等幅载条件下不存在。进而发展了等裂纹张开位移疲劳裂纹扩展测试法,检验裂纹闭合与疲劳裂纹扩展门槛值随降载方式的变化。

2) 用Iwin-Kies能量法推导了裂纹闭合现象下的K相近关系,修正了带裂纹闭合的有效应力强度因子概念。

3) 提出新的晶界滑移蠕变模型并导出瞬态蠕变方程,描述了多晶体材料瞬态蠕变与晶粒大小及晶界析出相颗粒分布的关系。结合由晶粒内位错运动导致的蠕变方程,得出三阶段蠕变曲线的理论公式。此成果被LPTi公司接受为发动机部件寿命分析的基本方程之一。

4) 著《金属材料寿命演变》一书,由中国科技大学出版社出版。

5) 发展了蠕变疲劳综合理论(The Integrated Creep-Fatigue Theory),全面地系统性地阐述了基于微观位错运动机制产生的本构关系和损伤累积过程,导出裂纹萌生和扩展以及兼并材料内部分布损伤的方程。此方程自然包含任意载谱(包括热机械循环载谱)下疲劳与蠕变和环境影响(如氧化)相互作用关系,是为全寿命预测的基石理论。

6) 导出低周疲劳的纯物理关系式(无需实验确定参数),经多种材料的实验数据验证。目前正研究高周疲劳的相应关系。

7) 发展了三维应力强度因子权函数公式,可应用于三维部件的断裂(疲劳裂纹扩展)分析。

8) 基于以上成果,为加拿大国防部及北美各航空和汽车公司进行研发设计服务,项目包括:

a. 预测性寿命管理系统

b. 发动机失效模式影响及原因分析(FMEA)

c. 镍基合金、不锈钢和铸铁的高温低周疲劳和热机械疲劳(恒温、温力同相、温力反相及带温度恒持的约束性热疲劳)

d. 等载恒持对钛合金疲劳寿命的影响

e. 前期蠕变对镍基合金和钛合金疲劳寿命的影响

f. 发动机涡盘的损伤容限分析

g. 发动机燃烧室,导向叶片及涡轮叶片的(蠕变和热机械疲劳)寿命分析

更详细的研究成果见https://www.researchgate.net/profile/Xijia_Wu (ResearchGate主页)